Copyright © 2018 Zhejiang Guangming Plastic Machinery Co., Ltd All rights reserved

浙ICP备07001420号 Powered By: www.300.cn

NEWS

Company News

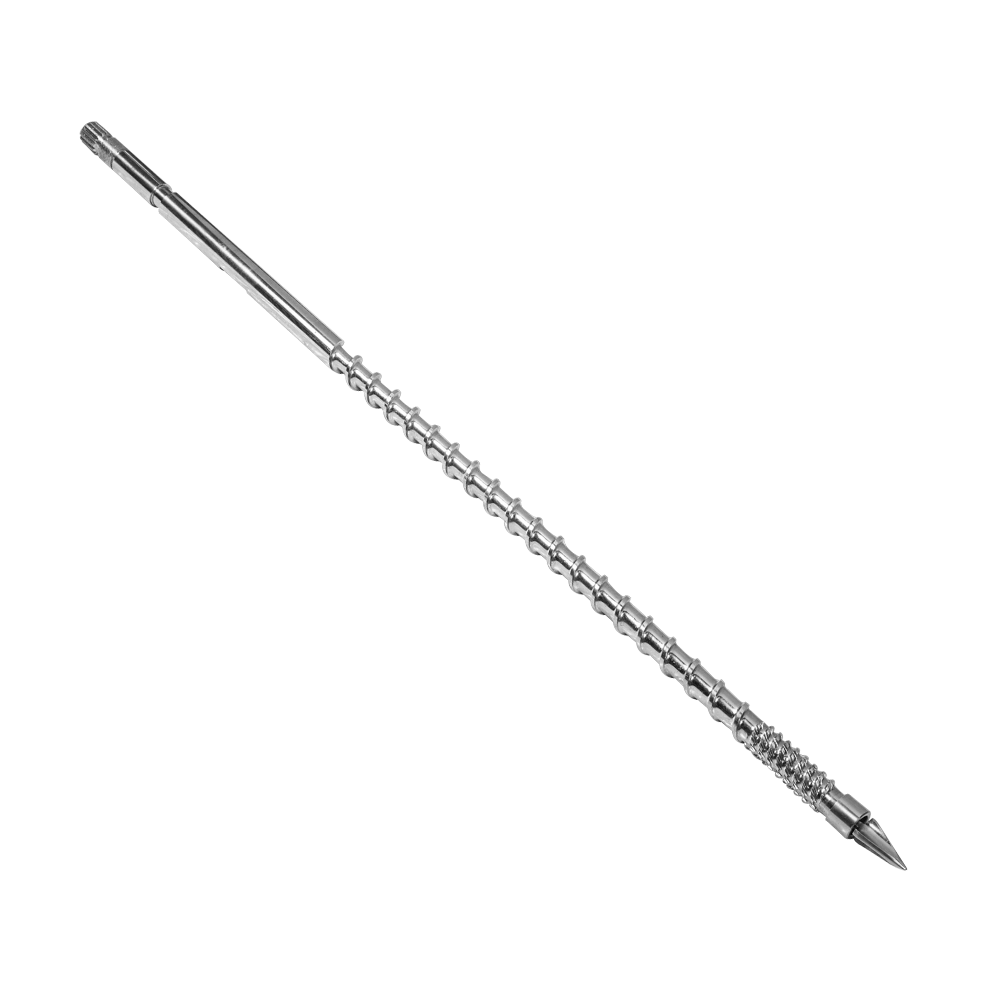

Conical Twin Screw and Barrel

Screw and Barrel for Extruder Maintenance Process Introduction

The manufacturer of Screw and Barrel for Extruder tells you that the extruder screw intuitively understands the wear phenomenon of wearing parts. Now the general twin-screw extruder needs to use a large amount of cleaning material to clean the machine when changing colors, which is time-consuming and power-consuming. and waste raw materials, and the split twin-screw extruder can solve this problem. The Screw and Barrel for Extruder manufacturer tells you that when changing the color, it only takes a few minutes to quickly turn over the barrel for manual washing.

Screw and Barrel for Extruder manufacturers tell you that you can find out the wear level of the inner liner of the screw element barrel at any time, and you can also analyze the turbidity process by viewing the melt profile on the entire screw, so that you don't have to or use less Cleaning the material, then doing useful repairs or replacements, and then pulling out the screw as a whole, while the split twin-screw doesn't have to, just loosen how many bolts in the twin-screw extruder.

Screw and Barrel for Extruder manufacturers tell you that the rolling worm gear box handle device lifts the upper half of the barrel to open the entire barrel. When repairing, the heating and cooling system of the ordinary twin-screw extruder often needs to be removed first. Then go back to repair, which not only shortens the repair time, but also reduces the labor intensity. It will not be discovered when there is a problem with the extruded product, which will cause unnecessary waste and reduce production costs. When manufacturing masterbatches, it is often necessary to change colors. The Screw and Barrel for Extruder manufacturer tells you to save money if you need to replace the product, opening the open machining area in minutes.