Copyright © 2018 Zhejiang Guangming Plastic Machinery Co., Ltd All rights reserved

浙ICP备07001420号 Powered By: www.300.cn

NEWS

Company News

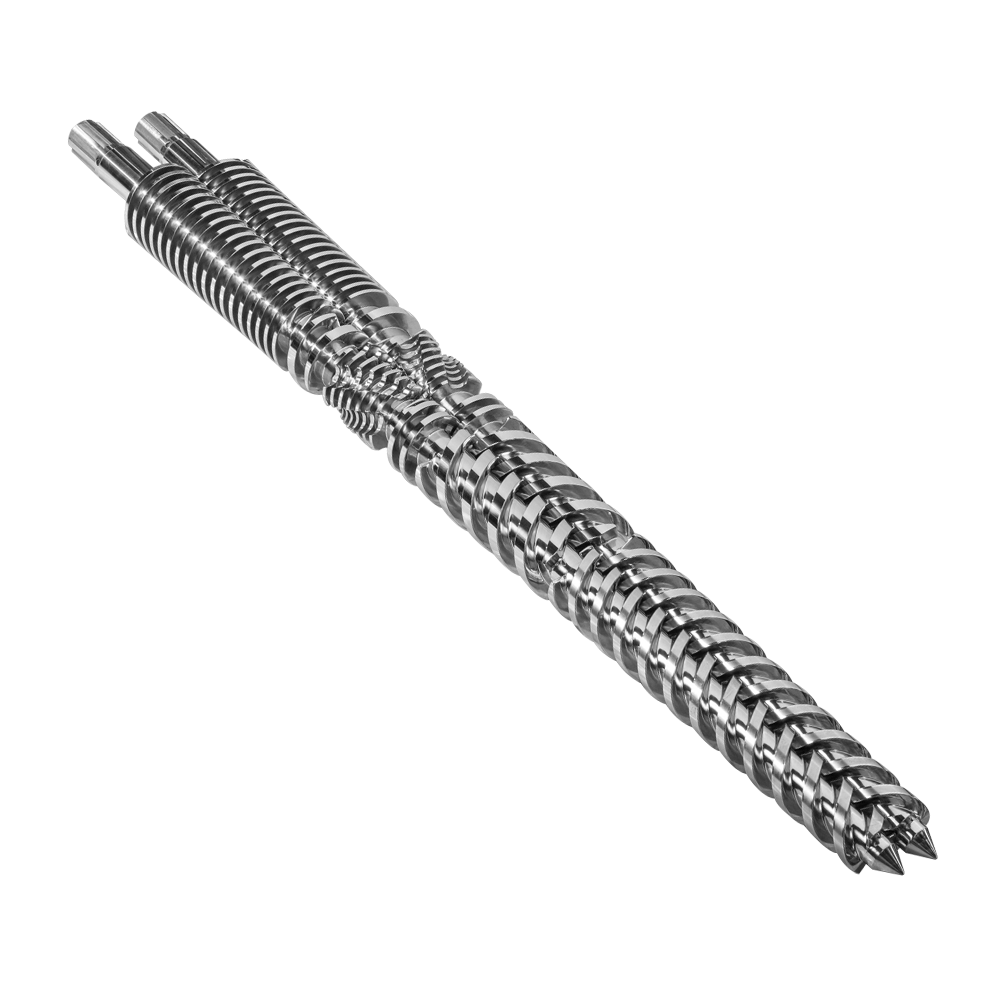

Conical Twin Screw and Barrel

How to properly maintain Screw and Barrel for Pelletizer Machine

Screw and Barrel for Pelletizer Machine is composed of thread and cylinder. The screw has a long hole along the center line for cooling water. The tail of the screw rod is installed in the thrust bearing to prevent the screw from being pushed out by the reaction force when squeezing the rubber. Here's how to maintain it effectively.

Screw and Barrel for Pelletizer Machine Care:

1. Clean off the dust and oil on the screw.

2. Check the wear condition of the screw. If the wear is slight and there are some scratches, you can use fine oil stone or fine emery cloth to grind it to restore its smoothness. And record the diameter of the screw working surface for use in the next maintenance.

3. Check the temperature of some screws to keep them within the operating temperature range.

4. Check whether the alarm system of some equipment is in good condition, whether the connection of electrical lines is safe and reliable, whether various pipelines are smooth, and whether oil pollution is blocked. The manufacturer of Screw and Barrel for Pelletizer Machine tells you that once there is a blockage, it is necessary to repair, adjust and test each safety alarm device in time to ensure the reliability and accuracy of its operation.